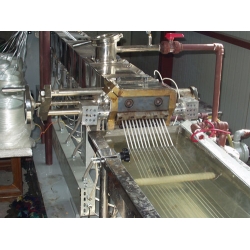

Plastic extruder is a kind of plastic machine which can be divided into continuous extruder and discontinuous extruder. During the run of plastic extruder, you should pay attention to many things.

The preparation work before drive of plastic extruder:

1. When start the operation equipment, the speed should from slow to fast, to check up whether the operation is normal and do observe the working condition.

2. The plastic which used to the extruder processing must meet the requirements of dry, if it is necessary, the material should process drying once more.

3. Open the heater and do heat the head and body of machine to rise their temperature to achieve the set required value. Besides the temperature of parts of plastic extruder should keep warm for about 40 minutes, to make the temperature inside and outside be accordance.

4. What’s more, sometimes, you should replace perforated plate, strainer and add abundant lubricating oil. The perforated plate can be used only it is clean thoroughly.

The importance for Plastic Pelletizing Machine

1. Before the plastic is extruded, anyone should not stand the dead ahead of exit.

2. Operate the machine with low speed. Operate the machine with no material to see whether there is problem of screw and instrument of electrical machine and electric current, whether the pressure gage is normal. The idling time of single screw extruder should as short as possible to prevent the grind of screw and screw, scratch between screw and charging barrel.

3. Add the material gradually and step by step. When the plastic is extruded and the run speed of screw achieve the normal run speed, you can add material with large quantity.

4. After the plastic is extruded, you should guide the extrudate to cool equipment and drag equipment which have opened before.

Stop the plastic extruder

1. Stop adding material. Do squeeze out the plastic in plastic extruder, and then close power of charging barrel and machine for next using.

2. At the time close the power of main machine, you also should close the power of auxiliary machine.

Other tips: do not operate cold machine. Because at that time, plastic extruder is not warm enough, if you operate it, the screw of plastic machinery, especially the old plastic extruder can easily twist off the screw. There is an effective method, before operation, heat the machine to the need temperature, then turn the coupling part with hand. If the turning is smoothly, then you can start the machine.